WEAR AND TEAR SOLUTIONS

There are many wearplates and other type of wear solutions on the market to fight against wear, earthmoving, recycling, mining, mixing minerals etc. All are devastating processes that cost the industry millions every year. Rather than replacing components, consider extending their lifespan. This approach is more cost-effective because it reduces downtime.

Wear disc / plate Pro 6072 is a micro alloyed black chrome plate that has a guaranteed Hardness through the full thickness of above 60 HRc.

This is the only wear disc on the market that offers full hardness throughout the full thickness of the plate!

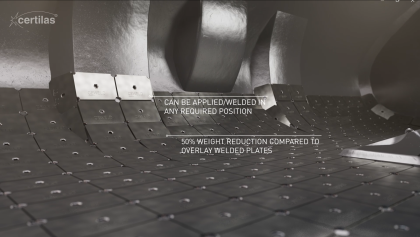

100 x 150 x 5 mm is the size that makes the plate easy to apply in any position and without lifting equipment. Simply tack welding at the prepared corners and enjoy a lifespan you’ll never saw before.

No Dilution

There is no dilution with the base metal, ensuring full high hardness throughout the plate’s thickness.

Reduced heat

The Wearplate pro ensures that the heat impact on the base metal is reduced, preventing loss of strength.

Manageable size

The size of the Wearplate pro (150x100x5mm) makes it easy to transport and apply.

10 times faster

The Wearplate pro is 10 times faster to apply than overlay welding by SMAW (Shielded Metal Arc Welding).

Convenience

for the welder, suitable for more applications.

Pattern design

The Pattern of the Wearplate pro allows spaces between the plates, offering more wear resistance.

Can be applied in any required position

The wearplate pro is versatile and can be placed in all positions

50% weight reduction

It weights 50% less compared to overlay welded plates, this can lead to operational efficiency.

Individual replacement

It is possible to replace individualy if needed. The Wearplate Pro can also be cut by normal flame.

These features make the Wearplate Pro 6072 an efficient and convenient option for industries looking to extend the life of their equipment and surfaces exposed to harsh wear conditions.

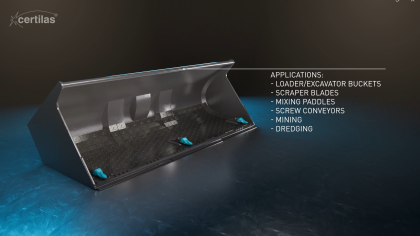

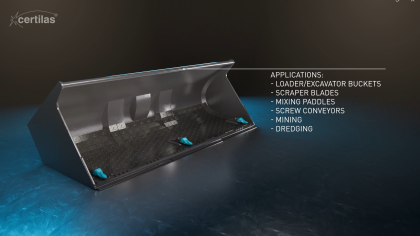

Applications for the Wearplate pro are:

- Loader/excavator buckets

- Scraper blades

- Mixing paddles

- screm conveyors

- Mining

- Dredging

- mutch, mutch more.