- productspecificaties

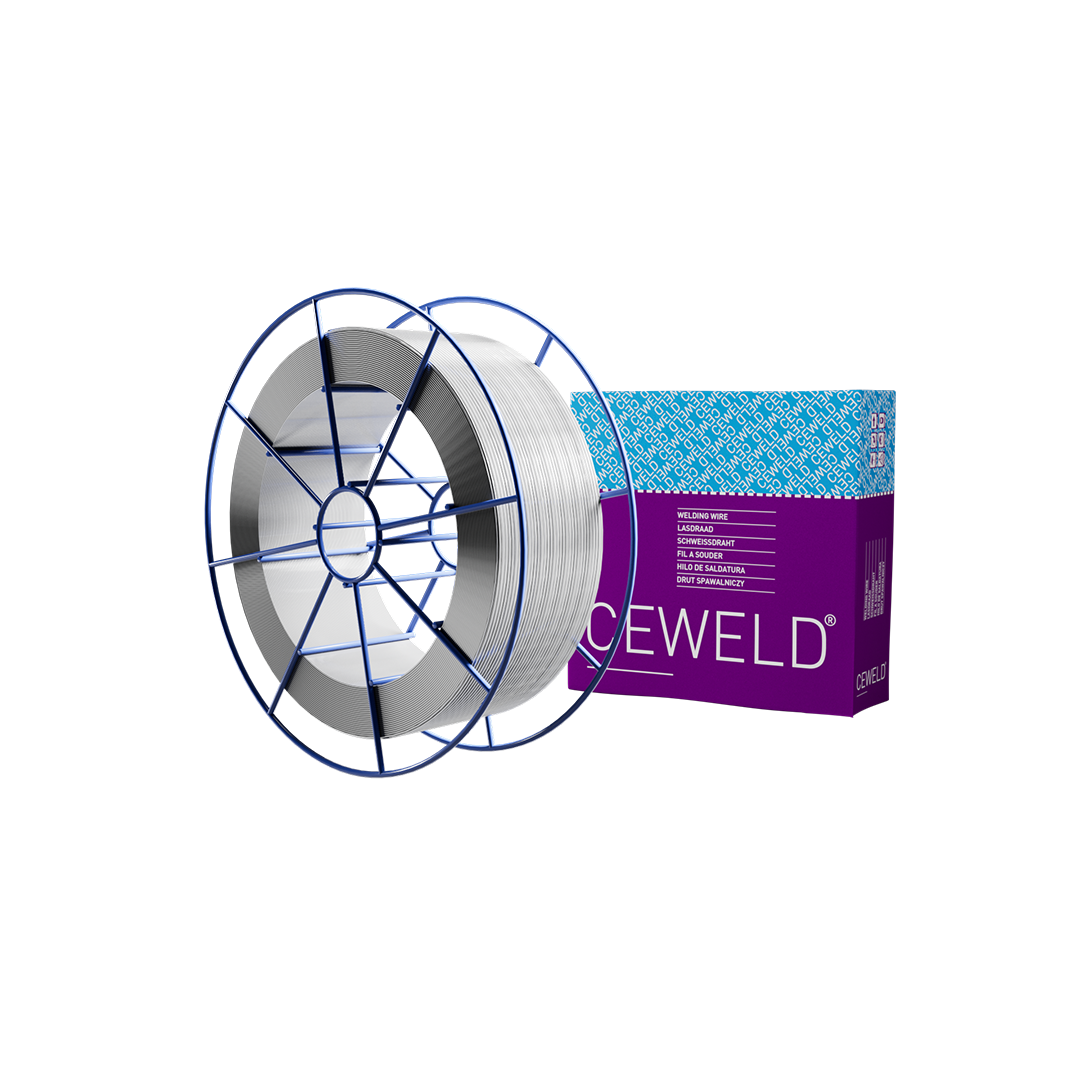

- Verpakkingen

- vraag offerte

Stabilization with niobium and titanium gives it the advantages of both these ferritic structure stabilizers: Titanium minimizes grain growth in Weld Metal zones (WM) due to titanium nitride (TiN) precipitation in the still liquid metal in these zones, thus avoiding the risk of brittleness, which may sometimes occur when very thick welds are made (> 3 mm of sheet metal to be welded). Niobium traps the residual C and N through its transfer of between 85 and 95% in the welding arc under all standard welding conditions, thus avoiding any risk of inter granular corrosion in the WM.

1.4000, 1.4002, 1.4016, 1.4057, 1.4740, 1.4742, 1.4057, 1.4059, 1.4741, 1.4509, 1.4510, 1.4511, 1.4512, 1.4520, 1.4712, 1.4713, 1.4724,

X7Cr14, X12Cr13, X17CrNi16-2, X6Cr13, X6CrAl13, X6Cr17, X17CrNi16-2, X2CrTiNb18, X3CrTi17, X3CrNb17, X2CrTi12, X2CrTi17, X10CrSi6, X10CrAlSi7, X10CrAlSi13, X10CrAlSi18

UNS S40300, S40500, S40900, S41000, S42900, S43000, S43035, S43036, S43100, S44200

AISI 403, 405, 409, 410, 429, 430, 430Cb, 430Ti, 439, 431, 442

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Hardness |

|---|---|---|---|---|

| As Welded | 310 | 450 | 25 | 140 HRc |