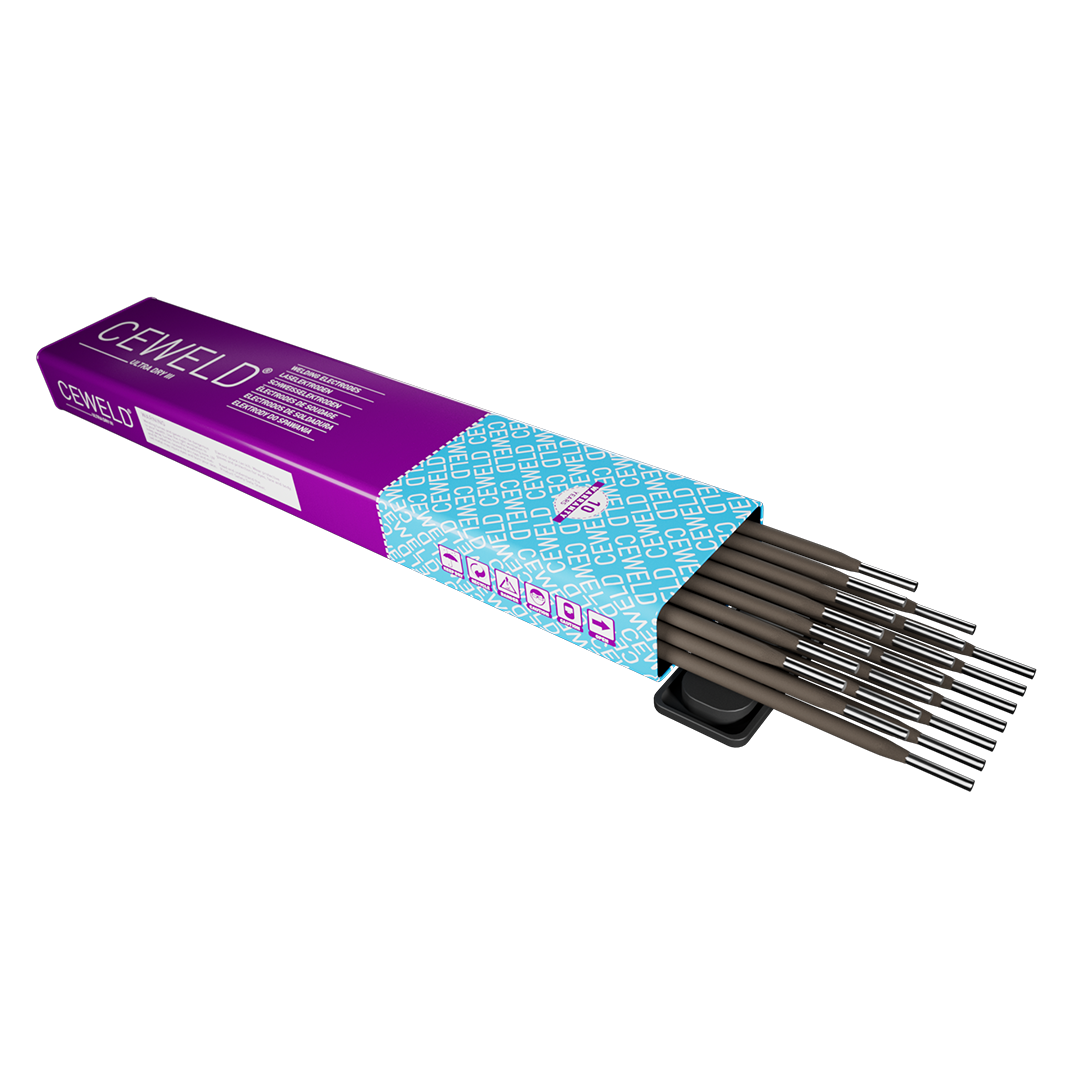

- spécifications du produit

- conditionnement

- demander un devis

Due to the Mo-content, abrasion resistance can be kept also with increased temperatures. For Hardfacing of more than 3 layers it is recommended to buffer with an electrode like CEWELD E DUR 350 Kb that delivers a welding deposit of less hardness. Overlays on steel with high tensile strength should be buffered with CroNi 29/9 HL or 4370 HL.

Up to 3 times faster! (less current with more deposit)

No slag losses compare to 40% loss with standard electrodes.!

Low amperage offers much lower heat input!

6 mm is ideal to weld in position and on sharp edges!

Moisture resistant coating even in extreme humidity conditions!

Tubular Hardfacing alloy for Sugar Mill knives and Hammers, Clinker Crushers, Liner plates, Ripper tines, Mixer blades, Gravel washing equipment, Ceramic mixer blades, Paddles, Extruders.

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Hardness |

|---|---|---|---|---|

| As Welded | 62 HRc |