- PRODUCT SPECIFICATIONS

- PACKAGING

- Ask quotation

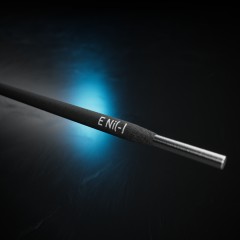

CEWELD®E Ni(-) is for joining and cladding gray and malleable cast iron, also suitable for joint welding between steel, copper and copper alloys, especially for maintenance and repair. Also for joining with steel, copper and monel.

Areas of application are:

Power generation industry, build-up welding and repairs, petrochemical and chemical industry, industry

CEWELD®E Ni(-) is for joining and cladding gray and malleable cast iron, also suitable for joint welding between steel, copper and copper alloys, especially for maintenance and repair. Also for joining with steel, copper and monel.

Areas of application are:

Power generation industry, build-up welding and repairs, petrochemical and chemical industry, industry

CEWELD®E Ni(-) exhibits excellent welding properties with easily controllable flow behavior and enables spatter-free welding with very low current. Due to the very low heat input and the unique composition of Ni, the transition zone remains easily workable and is therefore well suited as the first layer in multi-layer welding. The weld metal has no bonding defects!

Preheating is recommended to slow down the cooling rate, if you cannot control the cooling rate, it is better to keep the workpiece at a low temperature during welding and hammer immediately after welding.

Grey Cast Iron, EN 1561: EN-GjL-150, EN-GjL-200, EN-GjL-250, EN-GjL-300, EN-GjL-350, GG-15, GG-20, GG-25, GG-30, GG-35, GG-40,

EN 1563: EN-GJS-400-15, EN-GJS-400-18, EN-GJS-450-10, EN-GJS-500-7, EN-GJS-600-3, EN-GJS-700-2 G GG-40, G GG-45, G GG-50, G GG-60, G GG-70, G GG-80

Malleable cast iron: EN GJMB 350 - ENGJMB 650

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Hardness |

|---|---|---|---|---|

| As Welded | >262 | >276 | >3 | 160 HB |