- PRODUCT SPECIFICATIONS

- PACKAGING

- Ask quotation

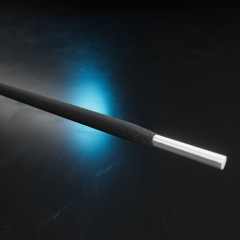

CEWELD® E DUR CE-Tube WC2 has a CCrCoZrAl matrix intercalated with tungsten carbides, making it an extremely wear resistant grade for most hardfacing applications.

The main areas of application are the coating and rebuilding of stabilizers and other oilfield tools where maximum protection is required. Also for screws, impellers, mixer plates in the brick and clay industry and for decanter screws in the food and chemical industries where corrosion resistance is required.

CEWELD® E DUR CE-Tube WC2 has a CCrCoZrAl matrix intercalated with tungsten carbides, making it an extremely wear resistant grade for most hardfacing applications.

The main areas of application are the coating and rebuilding of stabilizers and other oilfield tools where maximum protection is required. Also for screws, impellers, mixer plates in the brick and clay industry and for decanter screws in the food and chemical industries where corrosion resistance is required.

CEWELD® E DUR CE-Tube WC2 forms an extremely hard matrix of cobalt, chromium, aluminum, zirconium carbides with an extremely high tungsten content during welding, which improves the wear resistance against abrasion 4 to 8 times compared to C-Cr. alloys. Our knowledge of hardfacing is based on practical experience and years of testing with many different processes and alloys. max. 3 Layers

Sinter plant parts, Swing hammers, Drilling surfaces, Stone crushers, Fan blades, Coke pusher shoes and crushers segments, Shovel, Cement mill parts, Earthmoving equipment, etc.

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Hardness | |

|---|---|---|---|---|---|

| As Welded | 65 HRc |